Used potato farming machinery for sale (41)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Agricultural machinery Potato farming machinery

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeEVO 290 Airsep

Call

Condition: used, Year of construction: 2018, front tire size: 850er Bereifung auf 30.5 Felge, rear tire size: 850er Bereifung auf 30.5 Felge, tire size: 850er Bereifung auf 30.5 Felge, Tyres (front): 850 tyres on 30.5 rims, Tyres (rear): 850 tyres on 30.5 rims, Area performance: 926, Number of rows (2-row), Trailed, Hectare counter_____good condition, ready for immediate use, Cloadsep finger separator, Storage location: customer

Gujdjx Ay U Rspfx Ab Ajk

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeGT 170

Call

Condition: used, Year of construction: 2021, operating hours: 1,000 h, Equipment: compressed air brake, GT 170

0010 Used Grimme Potato Harvester, 2-row

GT 170 S - HE

0030 PTO shaft 540 rpm with overload clutch

0040 Hydraulic slope compensation

0050 Hydraulic axle steering

0060 Tyres 400/70-20 AS

0070 Ridge intake via trailed unit

0080 Intake unit with 4

0090 trailed, suspended coulters

0100 Coulter spacing

0110 540, 580 or 620 mm

0120 2- or 3-blade share

0130 2 flat ridge rollers

0140 Haulm intake rollers on the outside and

0150 central retaining rubber

0160 Mechanically driven, manually

0170 height-adjustable

0180 Rotor beater on the 1st sieving web

0190 Pick-off roller against the 1st sieving web

0200 1st sieving web pitch:

0210 28, 32, 35, 40, 45

0220 or 50 mm

0230 Bar spacing

0240 2nd sieving web pitch: 32, 35, 40 or 45

0250 mm High-performance, hydraulically

0260 driven unloading elevator

0270 Brake and lighting system

0280 Drawbar ball coupling Ø 80 mm

0290 Hydraulic drawbar adjustment

0300 Standard PTO shaft

0310 PTO shaft with 6 splines

0320 Drive with PTO speed 540 rpm

0330 Main drive with 22% speed reduction

0340 Row spacing 75 cm

0350 Intake width: 580 mm

0360 Half ridge rollers: Ø 390 mm, flat

0370 2-blade share

0380 Separately adjustable centre share

0390 TerraControl

0400 2 coulters

0410 Intake belt with mechanical drive

0420 Intake belt pitch 45 mm

0430 Pitch-dependent PU positive drive

0440 Clod breaker in intake conveyor

0450 Sieving channel width 1700 mm

0460 1st sieving web pitch 40 mm

0470 V2A stainless steel sheets in the shaker frame

0480 Rotor beater in the 1st sieving web with

0490 mechanical adjustment

0500 Shaker beater on the 1st sieving web with

0510 Speed adjustment via terminal

0520 Pick-off unit consisting of segment roller

0530 and double pick-off roller

0540 Guide for 1st pick-off unit/pick-off roller: comb

0550 2nd sieving web pitch 35 mm

Gujdpsxfcy Uefx Ab Aek

0560 2nd sieving web coated

0570 Clod breaker on the 2nd sieving web

0580 3rd sieving web pitch: 35 mm

0590 Fine haulm elevator below, hydraulically driven

0600 Fine haulm elevator belt below, pitch 40 mm

0610 Distributor star rollers under

0620 fine haulm elevator

0630 OptiBag, PU perforated pocket belt

0640 Cross elevator belt right and

0650 left running, with discharge hopper

0660 Air brake system

0670 Maximum speed 30 km/h

0680 Automatic axle centre finding and

0690 automatic slope control

0700 Tyre left: 620/50-22.5

0710 right: 320/85 R32

0720 Potato discharge via elevator on the right

0730 Without terminal

0750 ISOBUS

0760 Cameras

Listing

Schneverdingen

Schneverdingen

7,709 km

Potato technology

GrimmeSE 260 UB

Call

Condition: used, Year of construction: 2021, operating hours: 360 h, Equipment: compressed air brake, SE 260 UB

(0010) used Grimme SE 260 UB

(0020) Ball coupling Ø 80 mm

(0030) PTO shaft with 6 teeth

(0040) Drive with PTO speed 540 rpm

(0050) Direct drive

(0060) Row width 75 cm

(0070) Pick-up width: 600 mm

(0080) Half dam drums with collar:

(0090) Ø 390 mm

(0100) 3 blade share long

(0110) Separately adjustable center share

(0120) instead of center coulter discs

(0130) Mechanical digging depth adjustment

Gjdpfjw N Enwsx Ab Asuk

(0140) TerraControl

(0150) 2 coulter discs

(0160) Additional coulter disc outside

(0170) Sieve channel width 1500 mm

(0180) 1. Sieve belt pitch 35 mm

(0190) 1st sieve belt with lock connection

(0200) Pitch-independent friction drive

(0210) 1st sieve belt with support roller

(0220) Speed of 1st sieve belt - normal

(0230) V2A sheets in the oscillating frame

(0240) Oscillating beater in the 1st sieve belt with

(0250) Speed adjustment from the terminal

(0260) 2nd sieve belt pitch 32 mm

(0270) 2nd sieve belt with lock connection

(0280) 2nd sieve belt

(0290) Coarse weed belt spacing 200 mm

(0300) Belt 1st separator pitch 40 mm

(0310) H-profile hedgehog bar 1st separator

(0320) Scraper 1st separator

(0330) Smooth roller scraper

(0340) mechanical inclination adjustment

(0350) 1st and 2nd separator

(0360) height adjustment of scraper roller

(0370) 1st separator from terminal

(0380) slip monitoring 1st separator

(0390) and 2nd separator: SB hedgehog belt with flat

(0400) en

(0410) scraper 2nd separator

(0420) speed adjustment for 2 brushes

(0430) or finger belts from terminal

(0440) speed adjustment 1st and

(0450) 2nd separator from terminal

(0460) Speedtronic-Sep: automatic

(0470) speed adjustment of the

(0480) separators

(0490) feed chute right and left

(0500) additional mounted

(0510) Wide sorting table (930 mm)

(0520) Trash conveyor (280 mm)

(0530) Sorting conveyor with carriers

(0540) Trash conveyor adjustable

(0550) Differential speed to

(0560) Sorting table

(0570) Stone bunker with discharge conveyor

(0580) Front elevator with ultrasonic sensor

(0590) 6.0 t bunker

(0600) Bunker conveyor with cloth

(0610) Automatic bunker filling incl. automatic

(0620) for front elevator and filling optimization

(0630) Bunker head lowering

(0640) Air brake

(0650) Automatic axle centering and

(0660) Automatic tilting

(0670) Tires 800/45-30.5

(0680) Rear view camera attachments

(0690) including lighting

(0700) Camera attachments Transition from

(0710) 1st to 2nd separator,

(0720) Camera attachments Operating terminal VC 50 Joystick Box

(0740) instead of standard operating terminal

(0750) Mineral oil

(0760) Load-sensing kit with control cable to

(0770) tractor

(0780) Weather roof

Ready for use

Get information now

+49 201 858 95 507

+49 201 858 95 507

List now

*per listing / month

Listing

Uelzen

Uelzen

7,757 km

Potato technology

GrimmeEVO 280

Call

Condition: used, Year of construction: 2024, operating hours: 932 h, Equipment: compressed air brake, onboard computer, EVO 280

(0010) Grimme EVO 280 Gen II

(0020) Variant EVO 280 ClodSep

(0030) Country of use: Germany

(0040) Equipment for Germany

(0050) (Collection)

(0060) Full vehicle approval

(0070) EU type approval

(0080) Comfort-Line equipment package

(0090) Hitch: ball coupling Ø 80mm

(0100) Drive shaft (spline) drive shaft with 6 teeth

(0120) PTO speed drive with

(0130) PTO speed 1000 rpm

(0140) Drive: fully hydraulic drive

(0150) of all sieving belts and separating units

(0160) Transmission: direct drive unit

(0170) Intake width: 600mm

(0180) Ridge rollers: Ø 390mm

(0190) Spade share: 2-blade, long share

(0200) Separately adjustable center share

(0210) instead of middle disc coulters

(0220) Stone protection for spade share

(0240) Digging depth adjustment

(0250) Digging depth adjustment from the terminal

(0260) Depth control: TerraTronic

(0270) Automatic ridge center recognition disc coulters

(0290) Sieve channel width: 1500mm

(0300) Sieve web pitch: 40mm

(0310) Web connection: 1st sieve web with

(0320) Locking connection

(0330) Drive 1st sieve web:

(0340) Pitch-independent friction drive for 1st sieve web with support roller

(0360) V2A (stainless steel) sheets in shaker frame

(0370) Shaker in 1st sieve web with

(0380) Speed adjustment from terminal

(0390) Sieve web pitch: 32mm

(0400) Web connection: 2nd sieve web with

(0410) Drive 2nd sieve web:

(0420) Pitch-dependent PU positive drive for 2nd sieve web

(0440) Coarse weed web spacing: 200mm

(0450) Front retaining spring coarse weed web, standard version

(0470) Adjustable stripper combs from the terminal

(0490) Haulm shaft under coarse weed web

(0500) Oil cooler for self-contained hydraulic system

(0510) Web pitch 1st separation unit: 40mm

(0520) H-profile rubber finger rod 1st separation unit

(0530) 1st separation unit: smooth roller stripper

(0540) Tilt adjustment 1st and 2nd separation unit from terminal

(0560) Height adjustment stripper rollers 1st separation unit from terminal

(0580) Angle adjustment stripper roller 1st separation unit from terminal

(0600) Slip monitoring for 1st separation unit and 2nd sieve web

(0620) Trash discharge belt behind 1st separation unit

(0640) 2nd separation unit: finger belt with rods

Gujdoxvfruspfx Ab Ask

(0650) 2nd separation unit pitch: 40mm

(0660) H-profile rubber finger rod 2nd separation unit

(0670) Stripper 2nd separation unit, smooth roller stripper

(0690) 2nd separation unit triple stripper roller

(0700) Speed adjustment for ClodSep separation unit (upper/lower belt):

(0720) Speed adjustment for 2 brush/finger belts

(0740) from the terminal

(0750) Automatic tilt adjustment 1st and 2nd separation unit

(0770) Speed adjustment 1st and 2nd separation unit from terminal

(0790) Angle adjustment stripper roller 2nd separation unit from terminal

(0810) 3rd separation unit: finger belt with plates

(0820) 3rd separation unit ClodSep (upper belt)

(0830) Separation unit: two double-row finger stripper belts

(0850) Stripper 3rd separation unit: smooth roller/spiral roller stripper

(0870) Stripper 3rd separation unit: double stripper roller

(0890) Finger belt design: V-shaped finger arrangement for higher throughput

(0920) Height adjustment of finger belt, right and left, from terminal

(0940) Height adjustment of stripper rollers from 2nd separation unit from terminal

Listing

Barsinghausen

Barsinghausen

7,744 km

Potato technology

GrimmeSE 260 UB

Call

Condition: used, Year of construction: 2023, operating hours: 487 h, Equipment: compressed air brake, onboard computer, SE 260 UB

(0010) Grimme Potato Harvester, 2-row

(0020) Country-specific configuration for

(0030) Germany (pickup)

Gjdpfx Ajxl H Trjb Asuk

(0040) Single approval Germany

(0050) Anniversary special 10 years SE 260

(0060) Towing ball hitch Ø 80 mm

(0070) PTO shaft 1 3/8" with 6 splines

(0080) Drive with PTO speed 540 rpm

(0090) 3-speed gearbox

(0100) Row spacing 80 cm

(0110) Intake width: 620 mm

(0120) Half ridge formers with collar: Ø 390 mm

(0130) 2-blade share, long

(0140) Separately adjustable center share

(0150) in place of middle disc coulters

(0160) Stone protection for spade share

(0170) Digging depth adjustment from terminal

(0180) TerraControl

(0190) Automatic ridge centering

(0200) 2 disc coulters

(0210) Additional outer disc coulter

(0220) Web width 1700 mm

(0230) 1st web pitch 35 mm

(0240) 1st web with pin-type connection

(0250) Speed-independent friction drive 1st

(0260) Web with support roller

(0270) 1st web speed – standard

(0280) Stainless steel panels in shaker frame

(0290) Shaker on 1st web with

(0300) Speed adjustment from terminal

(0310) 2nd web pitch 32 mm

(0320) 2nd web with pin-type connection

(0330) Speed-independent friction drive 2nd

(0340) Web

(0350) Coarse haulm belt spacing 200 mm

(0360) Front return spring for coarse haulm belt

(0370) "Standard" version

(0380) 2 additional scrapers for

(0390) Coarse haulm belt

(0400) Belt 1st separator unit pitch 45 mm

(0410) H-profile hedgehog shaft 1st separator unit

(0420) Scraper 1st separator unit

(0430) Smooth roller scraper

(0440) Incline adjustment for 1st and 2nd

(0450) Separator unit from terminal

(0460) Height adjustment of scraper roller 1st

(0470) Separator unit from terminal

(0480) Slip monitoring 1st separator unit and

(0490) 2nd web

(0500) 2nd separator unit: Hedgehog belt with rods

(0510) Belt 2nd separator unit pitch 45 mm

(0520) H-profile hedgehog shaft 2nd separator unit

(0530) Scraper 2nd separator unit

(0540) Smooth roller scraper

(0550) Speed adjustment for 2

(0560) Brush or finger belts from terminal

(0570) Speed adjustment 1st and 2nd

(0580) Separator unit from terminal

(0590) Height adjustment of

(0600) Left finger/brush belt from terminal

(0610) Speedtronic-Sep: Automatic

(0620) Speed control of

(0630) Separator units

(0640) Feed chute right and left

(0650) Additionally mounted

(0660) Wide picking table (930 mm)

(0670) Admixture conveyor (280 mm)

(0680) Picking belt with carriers

(0690) Roller pre-cleaning, 5 rollers, radial

(0700) Infinitely adjustable, without container

(0710) Rollers for roller pre-cleaning

(0720) Spacing 20 mm

(0730) Discharge belt from roller pre-cleaner to

(0740) Stone bunker

(0750) Admixture belt design "rod belt"

(0760) Stone bunker with discharge belt

(0770) Intake elevator with ultrasonic sensor

(0780) 6.0 t bunker

(0790) Bunker belt with canvas

(0800) Automatic bunker filling incl. automation

(0810) for intake elevator and

(0820) Fill optimization

(0830) Bunker head lowering

(0840) Air brake

(0850) Speed 40 km/h

(0860) Automatic axle centering and

(0870) Slope compensation

(0880) Tires 710/45-26.5

(0890) 7" monitor and multiplexer of the

(0900) Grimme video system, up to 8

(0910) cameras possible

(0920) Camera as reversing camera, mounted,

(0930) incl. lighting

(0940) Camera on 1st web, mounted, incl.

(0950) lighting

(0960) Camera transition from 1st to 2nd

(0970) separator unit, mounted, incl. lighting

Listing

Alpen

Alpen

7,619 km

Potato technology

GrimmeEVO 280

Call

Condition: used, Year of construction: 2019, operating hours: 1,409 h, Equipment: compressed air brake, EVO 280

Gimme Potato Harvester

K80 Ball Hitch

6-tooth PTO drive shaft

540 rpm PTO drive

Direct drive

Row width 75 cm, Pick-up width: 580 mm, Diaphragm drums: 390 mm diameter

2-blade share

Separately adjustable center share - extra

TerraTronic

Automatic ridge centering

4 coulter discs

2 haulm deflector skids

Sieve channel width 1500 mm

1st sieve web pitch 40 mm

1st sieve web with lock connection

Pitch-independent Friction drive for the first screening belt with support roller

1st screening belt speed - fast

V2A plates in the oscillating frame

Oscillating agitator in the first screening belt with speed adjustment

2nd screening belt pitch 35 mm with lock connection

Pitch-independent friction drive for the second screening belt

VarioDrive: continuously variable drive for the first and second screening belts

Speedtronic-Web: forward speed and load-dependent

screening belt control

Coarse haulm belt spacing 280 mm

Gjdpjwgy S Hefx Ab Asuk

Stripper shaft adjustment from the terminal

1 haulm stripper shaft under the coarse haulm belt, hydraulic. Driven

Oil cooler for the company's own hydraulics

Belt of the first separator, pitch 40 mm

V-profile hedgehog bar of the first separator

Smooth roller scraper on the first separator

Tilt adjustment of the first and second separators from the terminal

Height adjustment of the scraper roller of the first separator from the terminal

Cleaning device in the hedgehog belt of the first separator

Angle adjustment of the scraper roller of the first separator from the terminal

Slippage monitoring of the first separator and the second screening belt

Trash removal belt behind the first separator

2nd separator: hedgehog belt with bars

Belt of the second separator, pitch 40 mm

V-profile hedgehog bar of the second separator

Smooth roller scraper of the second separator

Speed adjustment for 2 brush or finger belts

Automatic tilt adjustment of the first and second separators

Speed adjustment of the first and second separators

Angle adjustment of the scraper roller of the second Separator

3rd Separator: Hedgehog belt with bars - pitch: 40 mm

H-profile hedgehog bar for 3rd Separator

Height adjustment of the finger belt, right and left

Height adjustment of the scraper rollers for the 2nd Separator

Mechanical height adjustment of the scraper roller for the 3rd Separator

Bunker belt with cloth

Automatic bunker filling including automatic control for the front elevator and

Filling optimization

Bunker head lowering

Air brake

Automatic axle centering and automatic tilt control

Tires: 850/50 R30.5

ISOBUS control terminal CCI 1200 Touchscreen terminal

GBX 860 control box

ISOBUS

MemoryControl

Camera system

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

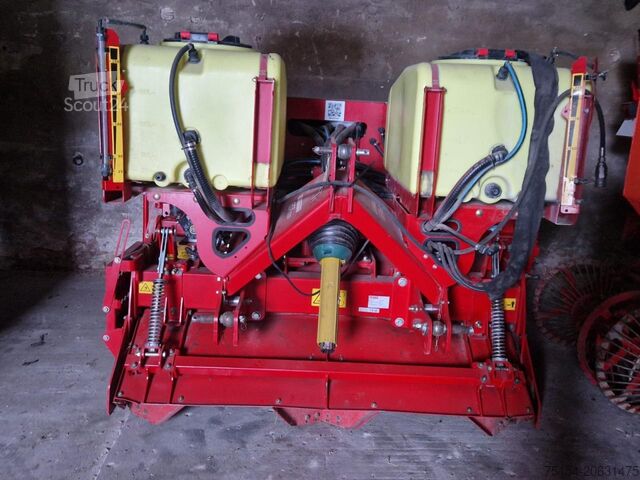

GrimmeGL32B + GF200+TS420

Call

Condition: used, Year of construction: 2019, Number of rows (2-row), rear-mounted_____2-row planting machine from 2019 with cage rollers, including GF200 ridge former from 2013 and TS420 crop protection equipment from 2018. Storage location: customer.

Gedpfxexzx Sxe Ab Asuk

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeSE 150-60 NB

Call

Condition: used, Year of construction: 2019, Equipment: compressed air brake, SE 150-60 NB

0010 Used Grimme potato harvester SE 150-60 NB XXL with powered axle

0020 1200 ha harvesting capacity

0030 Lower linkage K80, PTO shaft,

0040 2-line air brake system,

0050 Hydraulic support leg,

0060 Automatic ridge pressure relief

0070 Automatic ridge center tracking

0080 1st sieving conveyor with 40 mm pitch

0090 Stainless steel sheet in oscillating frame

0100 Agitator on the 1st sieving conveyor

0110 2nd sieving conveyor with 35 mm pitch

0120 Hydraulic adjustment of stripper combs from terminal

0130 Hedgehog belts 1 - 3 V 40 mm

0140 Slip monitoring for 1st separating unit

0150 Slip monitoring for 2nd sieving conveyor

0160 Speed adjustment for the 1st and 2nd separating units (electronic)

0170 1x picking platform, left side

0180 7500 kg bunker with lowered bunker head and wide axle

0190 Overload picking table for unloading while harvesting ("banana")

0200 Automatic bunker filling system,

0210 Automatic axle center/level adjustment

Gsdpfsxqt Hvox Ab Aouk

0220 Wheel drive hydraulic powered axle!

0230 VC50 control panel + 2x joystick box

0240 Cameras and work lights

0250 Tyres 710/50-30.5

Listing

Hövelhof

Hövelhof

7,725 km

Potato technology

GrimmeVARITRON 470

Call

Condition: used, Year of construction: 2021, operating hours: 1,515 h, power: 340 kW (462.27 HP), Equipment: front power take-off, VARITRON 470

(0010) Grimme self-propelled potato harvester.

(0020) VARITRON 470 RAD

(0030) Front power lift for haulm topper

(0040) Preparation for haulm distributor

(0050) Row width 75 cm

(0060) Pick-up width: 580 mm

(0070) Dam drums: Ø 390 mm flat

(0080) 2 blade share

(0090) Lift for tramline clearing

(0100) TerraControl

(0110) Hydraulically driven coulter discs (8

(0120) pcs.)

(0130) Pick-up belt 3000 mm

(0140) Pick-up belt pitch 40 mm

(0150) Pitch-dependent PU forced drive of the

(0160) pick-up belt

(0170) 1st sieve belt pitch 40 mm

(0180) Pitch-dependent PU forced drive 1st

(0190) sieve belt

(0200) oscillating beater in 1st sieve belt with

(0210) speed adjustment

(0220) from terminal

(0230) plucking roller against 1st sieve belt

(0240) guide 1st plucking unit / plucking roller:

(0250) brush

(0260) 2nd sieve belt pitch 35 mm

(0270) pitch-independent friction drive 2nd

(0280) sieve belt

(0290) receiving belt, 1st and 2nd sieve belt

(0300) reversible

(0310) rotor beater with speed adjustment in

(0320) 2nd sieve belt hydraulically

(0330) driven in series with oscillating beater

(0340) in 1st Sieve belt

(0350) Transfer belt to fine weed elevator

(0360) Pitch: 35 mm vulcanized

(0370) Speedtronic-Web: Automatic

(0380) Speed adjustment

(0390) of sieve belts INNOVATION

(0400) Segment roller with black segments

(0410) Guide 2. Plucking unit / plucking roller:

(0420) Brush

(0430) Segment rollers 1. MultiSep Ø 162 mm, 4

(0440) Lips

(0450) Clod rollers 1. MultiSep rubber

(0460) Fine weed elevator bottom hydraulically

(0470) driven

(0480) Belt fine weed elevator bottom pitch 40

(0490) mm

(0500) Scraper roller on the Fine weed elevator

Gusdpfx Aow Sfyxob Ajk

(0510) reversible from the terminal

(0520) OptiBag, PU perforated bag belt

(0530) Speedtronic elevator: Automatic

(0540) speed adjustment of the

(0550) elevator

(0560) Nonstop bunker with reversing

(0570) bunker floor

(0580) Lubrication system for bunker chain

(0590) Automatic bunker filling

(0600) Automatic axle centering and

(0610) Automatic tilting

(0620) Autopilot

(0630) Tires 270/95 R54 front axle with

(0640) track width 3.0 m

(0650) Tires rear left 900/60 R32,

(0660) Tires rear right 1050/50 R32

(0670) Hydrostatic independent wheel drive

(0680) Mercedes-Benz (MTU) engine OM 470 LA

(0690) Stage V with SCR exhaust technology

(0700) (AdBlue). Diesel fuels in accordance with

(0710) EN 590

(0720) Premium comfort cabin with additional

(0730) sound insulation,

(0740) leather seat with active ventilation and

(0750) seat heating as well as a cooling compartment

(0760) Video package 2

(0770) Visual Protect: CAN bus controlled

(0780) monitoring system

(0790) ErgoDrive operating concept with freely

(0800) configurable

(0810) direct access functions on the

(0820) multifunction lever and in the

(0830) control panel in the ergonomic armrest

(0840) as well as a CCI 100

(0850) and a CCI 50 touchscreen terminal

(0860) Clean Control (central adjustment function

(0870) for separators)

(0880) Automatic Lubrication system

(0890) Connection to myGRIMME

(0900) 6 LED headlights in the cabin roof

(0910) Additional lighting: 6 additional

(0920) headlights

(0930) HT 400

(0940) Row width 75

(0950) Haulm topper connection VARITRON

(0960) removable

(0970) Automatic haulm topper depth control

(0980) Integrated haulm distributor with

(0990) Discharge width control from the cabin

(1000) Post-harvest check

(1010) Machine inspection

(1020) Ready for use

Listing

Marxen

Marxen

7,708 km

Potato technology

GrimmeSE85-55

Call

Condition: used, Year of construction: 2020, operating hours: 245 h, omponents / E.10.010 Drawbar ball coupling Ø 80 mm / E.10.020 Hydraulic / Support foot / Standard PTO shaft / PTO shaft with 6 teeth / Drive with PTO shaft speed 540 / rpm / E.10.200 3-speed gearbox / Machine speed / norm

Guedpfx Absrywdxo Aok

Listing

Barsinghausen

Barsinghausen

7,744 km

Potato technology

GrimmeSE 260

Call

Condition: used, Year of construction: 2020, operating hours: 500 h, Equipment: compressed air brake, onboard computer, SE 260

(0010) mme potato harvester

(0020) Standard

(0030) National approval / Individual acceptance

(0040) Equipment for Germany (collection)

(0050) Ball coupling Ø 80 mm

(0060) PTO shaft with 6 teeth

(0070) Drive with PTO speed 540 rpm

(0080) 3-speed gearbox

(0090) Row spacing 80 cm

(0100) Pick-up width: 600 mm

(0110) Half ridge drums with collar: Ø 390 mm

(0120) 2-blade long share

(0130) Separately adjustable center share

(0140) Instead of center coulter discs

(0150) Stone protection for spade share

(0160) Mechanical Lifting depth adjustment

(0170) TerraControl

(0180) Automatic ridge centering

(0190) 2 coulter discs

(0200) Additional coulter disc outside

(0210) Screening channel width 1700 mm

(0220) 1st screening belt pitch 35 mm

Gedpfjv Tfvxjx Ab Ajuk

(0230) 1st screening belt with interlock connection

(0240) Pitch-independent friction drive

(0250) 1st screening belt with support roller

(0260) 1st screening belt speed - standard

(0270) V2A sheets in the oscillating frame

(0280) Oscillating agitator in the 1st screening belt

(0290) with speed adjustment

(0300) from the terminal

(0310) 2nd screening belt pitch 32 mm

(0320) 2nd screening belt with Lock connection

(0330) Pitch-independent friction drive

(0340) 2nd screening belt

(0350) Coarse haulm belt, 200 mm spacing

(0360) 2 additional scrapers

(0370) for coarse haulm belt

(0380) Belt for 1st separator, 45 mm spacing

(0390) H-profile hedgehog bar for 1st separator

(0400) Scraper for 1st separator

(0410) Smooth roller scraper

(0420) Tilt adjustment

(0430) 1st and 2nd separators from the terminal

(0440) Height adjustment for scraper roller

(0450) 1st separator from the terminal

(0460) Slip monitoring for 1st separator

(0470) and 2nd screening belt

(0480) 2nd separator: hedgehog belt with Bars

(0490) Belt for 2nd separator, 45 mm pitch

(0500) H-profile hedgehog bar for 2nd separator

(0510) Scraper for 2nd separator

(0520) Smooth roller scraper

(0530) Speed adjustment for 2

(0540) brush or finger belts from the terminal

(0550) Speed adjustment for 1st and 2nd

(0560) separator from the terminal

(0570) Height adjustment of the

(0580) finger/brush belt left of the terminal

(0590) Speedtronic-Sep: Automatic

(0600) Speed adjustment of the

(0610) separators

(0620) Feed chute, right and left

(0630) Additional installation

(0640) Wide sorting table (930 mm)

(0650) Trash conveyor (280 mm)

(0660) Inspection conveyor with flights

(0670) Roller pre-cleaner, 5 rollers, radial

(0680) Continuously adjustable, without container

(0690) Rollers for roller pre-cleaner

(0700) Spacing 20 mm

(0710) Discharge conveyor from roller pre-cleaner

(0720) to stone hopper

(0730) Stone hopper with discharge conveyor

(0740) Front elevator with ultrasonic sensor

(0750) 6.0 t hopper

(0760) Bunker conveyor with cloth

(0770) Automatic hopper filling system including automatic

(0780) for front elevator

(0790) and filling optimization

(0800) Bunker head lowering

(0810) Air brake

(0820) Automatic axle centering and

(0830) Automatic tilt control

(0840) Tires 710/45-26.5

(0850) 7" monitor and multiplexer of the

(0860) Grimme video system, up to 8 cameras

(0870) possible

(0880) Camera as rear view camera, mounted,

(0890) including lighting

(0900) Camera for 1st sieve belt, mounted,

(0910) including lighting

(0920) Camera for transition from 1st to 2nd

(0930) Separator, mounted, including lighting

(0940) Camera for picking table, mounted,

(0950) including lighting

(0960) Weather roof without side panels

(0970) Lighting for 1x weather roof

(0980) Control

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeKS 75-4 Krautschläger

Call

Condition: used, Year of construction: 2022, _____Long-distance travel device, PTO shaft, 4 rows, row spacing 75 cm, front and rear mounting, counter blade, storage location: customer

Gjdpfoxp Ev Tjx Ab Ajuk

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeEVO 290 NB

Call

Condition: used, Year of construction: 2019, operating hours: 2,469 h, Equipment: compressed air brake, onboard computer, EVO 290 NB

0010 Used Grimme potato harvester

0020 Side ridge intake with trailed ridge rollers

0030 Spring-mounted disc coulters

0040 Drawbar attachment for hitch (below PTO)

0050 Hydraulic support leg

0060 Hydraulic drawbar steering with automatic ridge center detection

0070 Automatic ridge relief

0080 Sieve channel width 1500 mm

0090 Sieve web with rod spacing of 28, 32, 35, 40, 45, or 50 mm (chain/belt connection)

0100 Stainless steel plates (V2A) in the shaker frame

0110 Sieve web (1st web) 28, 32, 35, 40, or 45 mm rod spacing

0120 Oscillating agitator on 1st sieve web with speed adjustment from terminal

0130 Coarse weed conveyor (200 or 280 mm spacing)

0140 Onboard hydraulics for TG drive

0150 Slippage monitoring of the first separating unit

0160 Height adjustment of scrapers

0170 1st separator controlled from the terminal

0180 Speed adjustment of the 2 finger conveyors from the terminal (with ClodSep separator)

0190 Speed adjustment 1st and 2nd TG from the terminal

0200 Adjustable mix-in conveyor

0210 Variable speed between sorting table and sorting conveyor

0220 Pre-elevator with ultrasonic sensor

0230 Discharge height of hopper: 4450 mm

0240 Automatic hopper filling

0250 Hopper capacity: 9000 kg

0260 Hopper filling automation incl. automation for pre-elevator and fill optimization

0270 2-stage motor for hopper emptying

0280 Warning system for tractor driver

0290 Tires: 710/50-30.5

0300 Hydraulic axle steering

0310 Automatic axle center detection and tilt control

0320 GDI, with ISOBUS diagnostic capability

0330 MemoryControl

0340 Air brake system and lighting

0350 Special equipment:

0360 Ball coupling Ø 80 mm

0370 PTO shaft with 6 splines

0380 PTO drive with 540 rpm

0390 Direct drive

0400 Row width: 75 cm

0410 Intake width: 600 mm

0420 Ridge rollers: Ø 390 mm

0430 2 long blade shares

0440 Separately adjustable center share

0450 Mechanical lifting depth adjustment

0460 TerraControl

0470 Automatic ridge center detection

0480 2 sieve channels, width 1500 mm

0490 1st sieve web, rod spacing 35 mm

0500 1st sieve web with chain link connection

0510 Partition-independent friction drive

0520 1st sieve web with support roller

0530 1st sieve web – high speed

Guedpfx Aexdphijb Aek

0540 Stainless steel plates in shaker frame

0550 Oscillating agitator in 1st sieve web, speed adjustable from terminal

0560 2nd sieve web, rod spacing 32 mm

0570 2nd sieve web with chain link connection

0580 Partition-independent friction drive

0590 2nd sieve web, VarioDrive INNOVATION

0600 Coarse weed conveyor, 200 mm spacing

0610 Adjustment for cleaning combs from terminal

0620 Oil cooler for onboard hydraulics (recommended for use above 30° C)

0630 1st separator belt, rod spacing 40 mm

0640 H-profile spiked roller, 1st separator

0650 Scraper, 1st separator

0660 Smooth roller scraper

0670 Tilt adjustment 1st and 2nd separator

0680 Height adjustment of scraper roller

0690 1st separator control from terminal

0700 Angle adjustment of scraper roller, 1st separator, from terminal and 2nd sieve web

0710 Lateral discharge conveyor behind 1st separator

0720 2nd separator: spiked belt with rods

0730 2nd separator belt, rod spacing 40 mm

0740 H-profile spiked roller, 2nd scraper, smooth roller scraper

0750 Tilt automation 1st and 2nd separator

0760 Speed adjustment 1st and 2nd ... (text ends here)

Listing

Marxen

Marxen

7,708 km

Potato technology

KuhnKrautschlegler BFP32

Call

Condition: used, Year of construction: 2022, Lighting/warning signs, trailed, / Height adjustment / _____ / Potato haulm topper with longitudinal chassis / 4 / rows / Support wheels / Potato haulm guide plates / Specially arranged flails / Plus longitudinal drive unit /

Gujdpfeqrrynox Ab Ajk

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeEVO 290 AIR SEB

Call

Condition: used, Year of construction: 2018, working width: 150 mm, Equipment: compressed air brake, lighting, Number of rows: 2, Row/body spacing: 75, Number of rows (2-row), Trailed, Steering axle, Control terminal, Slope compensation, Stone protection, Support foot/wheel, Wide-angle PTO shaft, 540 rpm, Cleaning unit, Hopper or transfer bunker, Ridge centering system_____Hopper volume 9 m³, Picking table, Stone/clod separation device, Coarse haulm belt, Storage location: customer

Guedpexakpgofx Ab Ask

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeEVO 290

Call

Condition: used, Year of construction: 2020, operating hours: 1,160 h, working width: 1,500 mm, Equipment: onboard computer, EVO 290

(0010) Used Grimme potato harvester

(0020) K80 ball hitch

(0030) PTO drive speed 1000 rpm

(0040) Adjustable center share

(0050) Automatic ridge pressure relief

(0060) Automatic ridge centering

(0070) Additional outer disc coulter

(0080) 1st sieving web, 40mm pitch

(0090) V2A stainless steel plate in shaker frame

(0100) Agitator on 1st sieving web

(0110) 2nd sieving web, 35mm pitch

(0120) Vario Drive

(0130) Speedtronic-Web

(0140) Adjustment for cleaning combs via terminal

(0150) 1 haulm stripper shaft under coarse haulm web

(0160) Height adjustment of stripper roller

(0170) Angle adjustment of stripper roller

(0180) Slip monitoring for 1st separating device

(0190) Slip monitoring for 2nd sieving web

(0200) Speed control for 1st and 2nd separating devices

(0210) Speedtronic-Sep

(0220) Intake elevator with ultrasonic sensor

(0230) Automatic bunker filling system

(0240) Potato discharge at moving floor bunker

(0250) Hydraulic folding device for potato discharge outlet

(0260) Automatic axle centering

(0270) Automatic slope compensation

(0280) Left tire 850/50R30.5

(0290) Right tire 1000/50R25

(0300) Hydrostatic wheel drive

(0310) 4x cameras with lighting/monitor

(0320) CCI 800 control terminal

(0330) Grimme GBX 860 / 871

(0340) Visual Protect

Godexavplspfx Ab Aeuk

(0350) MemoryControl

(0360) Area performance: 824 ha

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeSE 260 UB

Call

Condition: used, Year of construction: 2013, operating hours: 5,917 h, maximum speed: 25 km/h, front tire size: 600/55 26.5, working width: 150 mm, Equipment: additional headlights, compressed air brake, Tyres (front): 600/55 26.5, Operating hours: 5917, Number of rows: 2, 2-row configuration, Counter blade adjustment: electric, Trailed, Shares, Wide-angle PTO shaft, 540 rpm, Cleaning unit, K80, Hour meter_____Sieve channel width: 1500 mm, Share depth adjustment: mechanical, Axle: Standard axle with steering, K80 ball hitch: Yes, Mounting: Standard, Shares: 2-blade, Ridge center guidance: automatic, Sieve web pitch: 35 mm, Stripping roller height adjustment: hydraulic, 1st main web angle adjustment: hydraulic, 2nd main web angle adjustment: hydraulic, 1st main web height adjustment: hydraulic, 2nd main web height adjustment: hydraulic, Finger web height adjustment: hydraulic, Bunker head lowering, Potato discharge, Sorting table with sorting platform, Stone box, Stripping combs for coarse weed web: mechanical, Location: Customer site.

Gjdpfow S Dakox Ab Ajuk

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeSE 150-60 NBR

Call

Condition: used, Year of construction: 2015, working width: 1,500 mm, Equipment: compressed air brake, SE 150-60 NBR

0010 Used Grimme potato harvester

0020 Lower hitch K80, PTO shaft,

0030 Input gearbox 1000 rpm,

0040 2-circuit air brake system,

0050 Hydraulic support leg,

0060 Automatic ridge relief

0070 Automatic row centering

0080 1st sieving web, 40 mm pitch

0090 V2A sheet metal in oscillating frame

Gedsw Sfu Aopfx Ab Aeuk

0100 Agitators on 1st sieving web

0110 2nd sieving web, 35 mm pitch

0120 Deflector comb adjustment from terminal

0130 Hydraulic haulm flail shaft

0140 Slip monitoring on 1st separating device

0150 Slip monitoring on 2nd sieving web

0160 Speed adjustment 1st, 2nd separating device electric

0170 2nd platform

0180 6t bunker with wide axle

0190 Bunker fill automation

0200 Automatic axle centering/inclination compensation

0210 Wheel drive

0220 Control unit VC50, joystick box GBX 870 and 860,

0230 8-channel camera monitor,

0240 Tyres 710/50-30.5

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeKS 3000

Call

Condition: used, _____,Storage location:Customer

Godpfxexly Sne Ab Ajuk

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeEVO 280

Call

Condition: used, Year of construction: 2023, operating hours: 801 h, Equipment: onboard computer, EVO 280

(0010) Used Grimme Potato Harvester EVO 280 EasySep

(0020) K80 Ball Hitch

(0030) PTO Shaft 1 3/8" with 6 splines

(0040) PTO Drive Speed 1000 rpm

Guedpfjw Sfupex Ab Aok

(0050) Fully hydraulic drive for all conveyors

(0060) Harvesting depth adjustment from the terminal

(0070) Automatic ridge relief

(0080) Automatic ridge center detection

(0090) Additional external disc coulter

(0100) 1st sieving web, 40 mm pitch

(0110) Stainless steel (V2A) sheets in the shaker frame

(0120) Shaker head for 1st sieving web

(0130) 2nd sieving web, 35 mm pitch

(0140) Adjustment of cleaning combs from the terminal

(0150) Vine shaft under coarse haulm conveyor

(0160) Oil cooler for on-board hydraulics

(0170) 1st separating device, 40 mm pitch

(0180) Inclination adjustment of separating units from terminal

(0190) Angle adjustment of cleaning roller from terminal

(0200) Slip monitoring of 1st separating unit

(0210) Slip monitoring of 2nd sieving web

(0220) Trash discharge conveyor behind 1st separating unit

(0230) 2nd separating unit, 40 mm pitch

(0240) Automatic inclination for 1st and 2nd separating unit

(0250) Angle adjustment of cleaning roller from terminal

(0260) EasySep separating unit

(0270) Height adjustment of cleaning rollers from terminal

(0280) Turbo Clean

(0290) Comfort package for picking table

(0300) Cross conveyor for trash, reversible

(0310) Pre-elevator with ultrasonic sensor

(0320) 8 t bunker

(0330) Bunker filling automatic

(0340) Potato discharge at bunker head

(0350) Potato discharge for 2.20 m boxes

(0360) Hydraulic folding device for potato discharge

(0370) Automatic axle center detection

(0380) Automatic inclination control

(0390) Tires 850/50R30.5

(0400) Telescoping rear left axle

(0410) Central grease banks for bunker and axle

(0420) LED work lights

(0430) ISOBUS

(0440) ISOBUS operating terminal CCI 1200

(0450) ISOBUS operating terminal IBX 200

(0460) ISOBUS control unit IBX 200

(0470) ISOBUS control unit IBX 300

(0480) Memory Control

(0490) SmartView monitor

(0500) SmartView Pro camera package

(0510) Visual Protect Pro function monitoring

(0520) Speedtronic-Web

(0530) Speedtronic-Sep

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeEVO 280

Call

Condition: used, Year of construction: 2021, Equipment: additional headlights, compressed air brake, lighting, onboard computer, Number of rows: 2, Area performance: 410, Number of rows (2-row), on-board hydraulics, ridge press roller / cage roller, trailed, steering axle, performance monitor, operator terminal, slope compensation, sorting table, wide-angle PTO shaft, hectare counter, ISOBUS, bunker or transfer bunker, ridge roller, ridge center detection, haulm topper._____2 rows, axle steering, ridge pressure regulation, drawbar steering, slope compensation, sorting table, 5 cameras, web chains 35mm spacing, location: customer

Gusdpoxf Amuofx Ab Aok

Trust Seal

Dealers certified through TruckScout24

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeSE 150-60 NB

Call

Condition: used, Year of construction: 2016, operating hours: 1,439 h, Equipment: compressed air brake, onboard computer, SE 150-60 NB

0010 Used GRIMME potato harvester in series

0020 K80 ball hitch

0030 - PTO shaft with 6 splines

0040 - Drive with PTO speed 540 rpm

0050 - Direct drive

0060 - Row spacing 75 cm

0070 - Intake width 580 mm

0080 - Half ridge rollers: 390 mm

Gujdpsw Nzxlsfx Ab Aok

0090 - 3 long share blades

0100 Separately adjustable centre share

0110 instead of central disc coulters

0120 Stone protection for spade share

0130 Lifting depth adjustment from terminal

0140 Automatic ridge unloading

0150 Automatic ridge centre detection

0160 - 2 disc coulters

0170 - Sieve channel width 1500 mm

0180 - 1st sieving web, pitch 40 mm

0190 - 1st sieving web with lock joint

0200 - Pitch-independent friction drive

0210 1st sieving web with support roller

0220 Stainless steel plates (V2A) in oscillating frame

0230 Shaker on 1st sieving web with

0240 Speed adjustment from terminal

0250 - 2nd sieving web, pitch 35 mm

0260 - 2nd sieving web with overlapping

0270 connection

0280 - Pitch-independent friction drive

0290 2nd sieving web

0300 - Coarse haulm conveyor spacing 280 mm

0310 Adjustment for stripper combs

0320 from terminal

0330 1 haulm stripper shaft under the

0340 coarse haulm conveyor, hydraulically driven

0350 XXL separating device for NB incl.

0360 Height adjustment for stripping roller

0370 1st separating device from terminal and

0380 3rd separating device NB finger web

0390 - Web, 1st separating device, pitch 40 mm

0400 - H-profile finger rod on 1st separating device

0410 - Scraper for 1st separating device, smooth roller

0420 Scraper

0430 Cleaning unit in finger web of

0440 1st separating device

0450 Slip monitoring on 1st separating device and

0460 2nd sieving web

0470 - 2nd separating device: finger web with rods

0480 - Web on 2nd separating device, pitch 40 mm

0490 - V-profile finger rod on 2nd separating device

0500 - Scraper for 2nd separating device, smooth roller

0510 Scraper

0520 Cleaning unit in finger web of

0530 2nd separating device

0540 Speed adjustment for 1st and 2nd

0550 separating device from terminal

0560 - 3rd separating device: finger web with rods

0570 - 3rd separating device: NB finger web without

0580 admixture web, with left-hand intake chute

0590 - 3rd separating device: standard scraper

0600 - Web on 3rd separating device, pitch 40 mm

0610 2nd platform with intake chute and

0620 admixture cross conveyor

0630 - Picking table (1100 mm)

0640 7.5 t bunker with wide axle

0650 - Bunker conveyor with canvas

0660 Automatic bunker filling incl. automatic

0670 for pre-elevator and filling optimisation

0680 Lowerable bunker head

0690 - Air brake system

0700 Automatic axle centre detection and slope

0710 compensation

0720 7" monitor and multiplexer for GRIMME

0730 video system, up to 8 cameras possible

0740 Camera as reversing camera, installed,

0750 incl. lighting

0760 Camera for transfer from 1st to 3rd

0770 separating device, installed, incl. lighting

0780 Camera for picking table, installed, incl.

0790 lighting

0800 Camera for bunker head, installed, incl.

0810 lighting

0820 Visual Protect: CAN-bus controlled

0830 monitoring system

0840 VC50 control terminal + joystick box

0850 instead of standard control terminal

0860 Multifunction lever instead of

0870 right joystick box

0880 Speedtronic

0910 to tractor

0940 Tyres: 600/45-30.5 Alliance

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeKS 3000

Call

Condition: used, Year of construction: 1992, _____Underwent inspection, ready for operation, storage location: 17094 Pragsdorf

Gusdpfx Aew Tqm Heb Aek

Listing

Meppen-Versen

Meppen-Versen

7,587 km

Potato technology

GrimmeEVO 290

Call

Condition: used, Year of construction: 2022, operating hours: 601 h, Equipment: compressed air brake, onboard computer, EVO 290

(0010) Used GRIMME EVO 290

(0020) Performance Line

(0030) Drawbar eye coupling, diameter 80 mm

(0040) PTO shaft 1 3/4" with 20 splines

Guodpfx Aevpmg Rjb Ajk

(0050) Drive with PTO speed

(0060) rpm

(0070) Direct drive

(0080) Row width 75 cm

(0090) Intake width 580 mm

(0100) Ridge drums: diameter 390 mm

(0110) 3-blade share, long

(0120) Separately adjustable central share

(0130) in place of central disc coulters

(0140) Lifting depth adjustment from terminal

(0150) Automatic ridge pressure relief

(0160) Automatic ridge centering

(0170) 2 disc coulters

(0180) Additional outer disc coulter

(0190) Web channel width 1500 mm

(0200) 1st sieving web pitch 40 mm

(0210) 1st sieving web with lock connection

(0220) Pitch-independent friction drive 1st

(0230) sieving web with support roller

(0240) 1st sieving web speed - high

(0250) V2A panels in the shaking frame

(0260) Shaker on 1st sieving web with

(0270) Speed adjustment from

(0280) terminal

(0290) 2nd sieving web pitch 35 mm

(0300) 2nd sieving web with lock connection

(0310) Pitch-independent friction drive

(0320) 2nd sieving web

(0330) VarioDrive: stepless drive for

(0340) 1st and 2nd sieving web

(0350) Coarse haulm conveyor spacing 280 mm

(0360) Retaining spring front, coarse haulm belt

(0370) Heavy-duty version

(0380) Adjustment for cleaning combs from

(0390) terminal

(0400) 1 haulm cleaning shaft under

(0410) coarse haulm belt, hydraulically driven

(0420) Oil cooler for self-contained hydraulics

(0430) 1st separating device belt, pitch 40 mm

(0440) V-profile hedgehog roller, 1st separator

(0450) Scraper, 1st separator

(0460) Smooth roller scraper

(0470) Tilt adjustment 1st and 2nd separator

(0480) from terminal

(0490) Height adjustment for cleaning rollers

(0500) 1st separator from terminal

(0510) Angle adjustment for cleaning roller

(0520) 1st separator from terminal

(0530) Slip monitoring behind

(0540) 1st separator and 2nd sieving web

(0550) Trash removal conveyor behind

(0560) 1st separator

(0570) 2nd separator: hedgehog belt with rods

(0580) 2nd separator belt pitch 40 mm

(0590) V-profile hedgehog roller, 2nd separator

(0600) Scraper 2nd separator

(0610) Smooth roller scraper 2nd separator

(0620) Triple scraper roller

(0630) Automatic tilt control 1st and 2nd separator

(0640) Speed adjustment 1st and

(0650) 2nd separator from terminal

(0660) Angle adjustment for cleaning roller

(0670) 2nd separator from terminal

(0680) Turbo Clean

(0690) Wide inspection table (930 mm) without

(0700) trash conveyor

(0710) Basic comfort package for inspection table

(0720) Inspection conveyor with carriers

(0730) Pre-elevator with ultrasonic sensor

(0740) 9.0 t bunker

(0750) Bunker belt with fabric cover

(0760) Automatic bunker filling including automation

(0770) for pre-elevator and

(0780) filling optimization

(0790) Potato outlet at moving floor bunker for

(0800) box filling/drop brake

(0810) Potato outlet for boxes with width 2.20 m

(0820) Hydraulic folding mechanism for

(0830) potato outlet

(0840) Air brake system

(0850) Speed 25 km/h

(0860) Automatic axle centering and

(0870) automatic tilt control

(0880) Left tire: 850/50 R30.5,

(0890) right: /50 R25

(0900) Hydrostatic wheel drive with

(0910) Wide-angle PTO shaft and

(0920) hydraulic coupling

(0930) TriSys three-wheel chassis

(0940) GBX 860 control box

(0950) Mineral oil

(0960) Load-sensing kit with control line to

(0970) tractor

(0980) Standard nameplate and stickers

(0990) Operating manual included

Listing

Pragsdorf

Pragsdorf

7,875 km

Potato technology

GrimmeKS 75-4 Krautschläger

Call

Condition: used, Year of construction: 2014, Krautschläger 3m, 4 rows, 75cm row spacing, support wheels, PTO shaft, storage location: customer

Gsdpfx Aew Rkk Heb Asuk

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used potato farming machinery (41)

Now search TruckScout24 completely with more than 120,000 used vehicles.Browse the most popular categories:

- Agricultural Spare Parts & Accessories

- Conveyor Equipment For Agriculture

- Farm Tillage Equipment

- Forklift Tractors / Tow Tractors

- Grammer Special Agricultural Machinery

- Irrigation Systems / Irrigation Equipment

- Lawn Tractors / Ride-On Mowers

- Orchard And Vineyard Equipment

- Other Agricultural Machines

This may be of interest to you

Get information now

+49 201 858 95 507

+49 201 858 95 507

List now

*per listing / month